Automatic Fine Grills

Fine or coarse screening is the first step in the treatment of wastewater in sewage treatment plants. SCAE offers a system of machines organized to meet all treatment needs, with the possibility of customizing individual components for optimal process success. Various options are also available to improve operation, management and performance.

The parallel-tooth screen is installed in a reinforced concrete channel and is used for the separation of fine/medium sized solids from water in civil and industrial plants. It consists of a frame made from 5 mm thick AISI 304 stainless steel sheet inside of which is installed a sliding belt composed of self-cleaning filtering elements made from acetal resin with a filtering gap of 1 - 3 - 6 or 10 mm.

GDP

PARALLEL TEETH GRID GDP SERIES

Description

The parallel toothed screen is installed in reinforced concrete channels and is used to separate fine/medium sized solids from water in civil and industrial plants. It consists of a frame made from 5 mm thick AISI 304 stainless steel sheet inside of which a sliding belt is installed composed of self-cleaning filtering elements made from acetal resin with a filtering gap of 1 - 3 - 6 or 10 mm. The The filtering elements are driven by AISI 304 stainless steel bars which in turn are supported on the frame by means of rotating bushings in nylon, plates and washers in AISI 304 stainless steel. The unloading phase of the screened material is generated by the relative movement of the filtering elements and the inversion of the direction of operation of the belt itself; the machine is also equipped with a double cleaning system:

- N. 1 rotating brush: the brush ensures perfect cleaning of the filtration system after self-cleaning due to the relative movement of the filter elements. A suitable casing made of AISI 304 stainless steel sheet has the function of directing the screened material inside a collection bin.

- N. 1 Washing ramp: the machine will also be equipped with an integrative washing system with ramp and nozzles which, after the brush cleaning phase, washes the filter mat before returning it to the water.

Tensioning shaft, motor shaft and toothed crowns made of high-strength painted special carbon steel. The motorizations of the belt and of the brush are independent to guarantee an easy maintenance and spare parts and for an efficiency designed and sized for the work to be done.

Materials:

Version entirely in Aisi 304 stainless steel or Aisi 316 stainless steel Tension shaft, crankshaft and toothed crowns in special high-strength steel

Accessories:

Electric control panel

| Model | L[mm] | L1[mm] | H1 | TOTAL H | Power |

|---|---|---|---|---|---|

| GDP 500 | 500 | 480 | H Channel + 800 mm | H Unload + 1.000 mm | 0,37 |

| GDP 700 | 700 | 680 | 0,75 | ||

| GDP 1000 | 1000 | 980 | 1,1 | ||

| GDP 1200 | 1200 | 1180 | 1,1 |

Filtration light: 1 - 3 - 6 - 10 mm

The grid with parallel teeth GPD-T is installed in a tank in Aisi 304 stainless steel and is used for the separation of medium / fine-sized solid bodies from water, in civil and industrial plants. It consists of a frame made of 5 thick AISI 304 stainless steel sheet inside which a sliding belt is installed consisting of self-cleaning filter elements made of acetal resin with filtration light 1 - 3 - 6 or 10 mm.

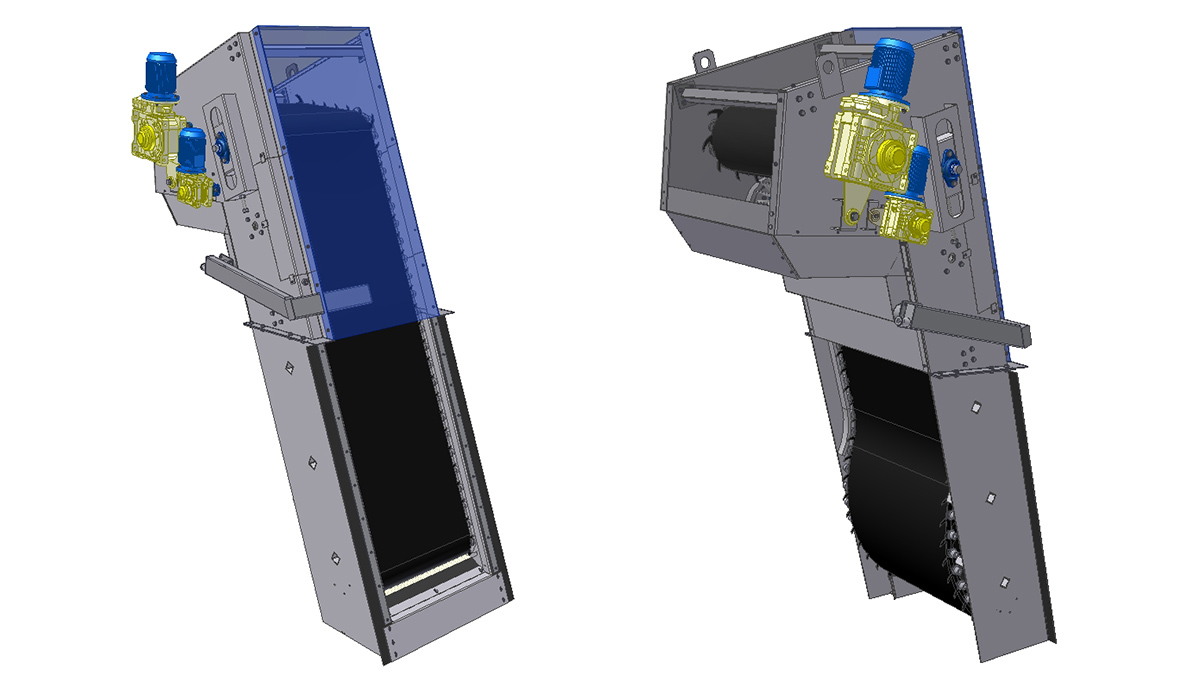

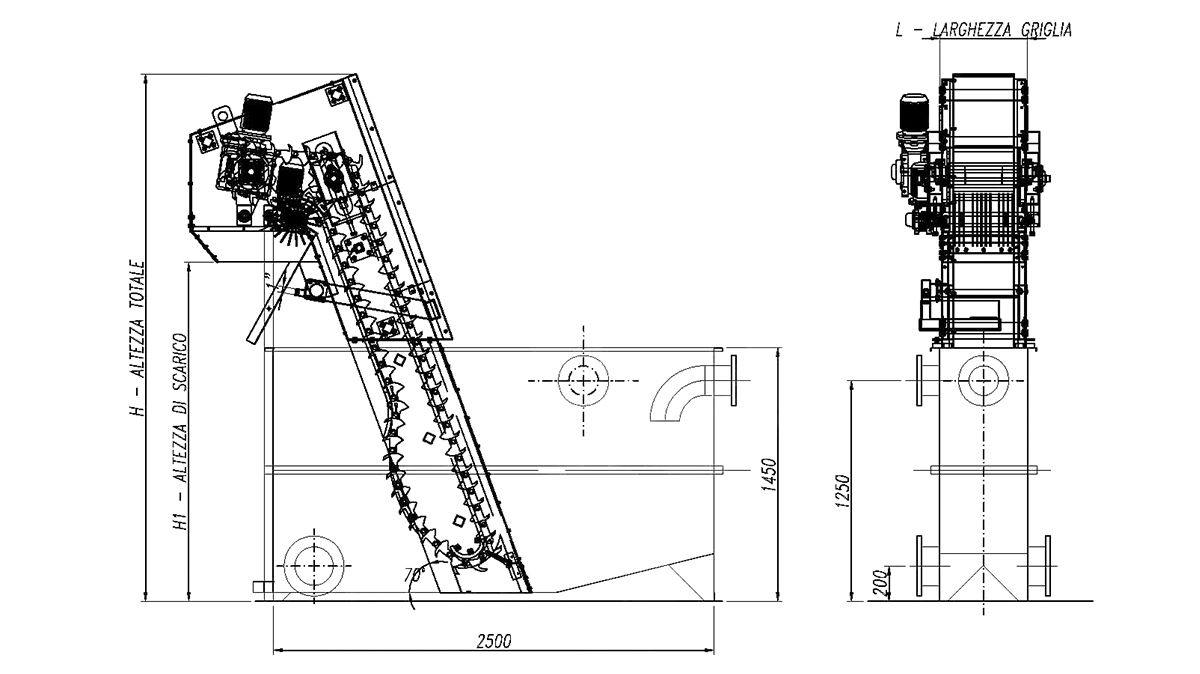

GDP-T

PARALLEL TEETH GRID HOUSED IN TANK GDP-T SERIES

Description

The Parallel Tooth Screen GPD-T is installed in an Aisi 304 stainless steel tank and is used for the separation of fine/medium sized solids from water in civil and industrial plants. It is constituted by a frame made of a 5 mm thick sheet of AISI 304 stainless steel inside which a sliding belt is installed composed of self-cleaning filtering elements made of acetal resin with a filtering span of 1 - 3 - 6 or 10 mm. The filtering elements are driven by AISI 304 stainless steel bars which in turn are supported on the frame by means of rotating nylon bushings, plates and washers in AISI 304 stainless steel. The discharge phase of the screened material is generated by the relative movement of the filtering elements and the inversion of the direction of operation of the belt itself; the machine is also equipped with a double cleaning system:

- N. 1 rotating brush: the brush ensures perfect cleaning of the filtration system after self-cleaning due to the relative movement of the filter elements. A suitable casing made of AISI 304 stainless steel sheet has the function of directing the grilled material inside a collection bin.

- N. 1 Washing ramp: the machine will also be equipped with an integrative washing system with ramp and nozzles which, after the brush cleaning phase, washes the filter mat before returning it to the water.

Tensioning shaft, crankshaft and sprockets in special high-resistance painted carbon steel. The motorizations of the carpet and the brush are independent to ensure ease of maintenance and spare parts and for an efficiency designed and sized to art for the work to be done.

The grid housing tank is made of Aisi 304 stainless steel, thickness 20/10, bent and ribbed with tubular uprights 50 x 50 x 2 and tubular crossbeams 50 x 20 x 2; it is complete with inviting bottom with:

- DN150 pipe inlet with conveying curve

- flanged overflow pipe DN150

- side water outlet with DN200 flanged pipe

- 2 ”rear sleeve, as a bottom drain

Materials:

Version entirely in Aisi 304 stainless steel or Aisi 316 stainless steel

Tensioning shaft, motor shaft and toothed crowns in special high-strength steel

Accessories:

Electric control panel

| Model | L[mm] | H1 | TOTAL H | Power |

|---|---|---|---|---|

| GDP/T 500 | 500 | H Basin + 500 mm | H Unload + 1.000 mm | 0,37 |

| GDP/T 700 | 700 | 0,75 | ||

| GDP/T 1000 | 1000 | 1,1 | ||

| GDP/T 1200 | 1200 | 1,1 |

Filtration light: 1 - 3 - 6 - 10 mm

The rotostrainer is a piece of equipment for the fine screening of wastewater. The liquid to be treated enters a feed tank, the solid particles it contains come into contact with a filter cylinder and are then removed.

RTS

RTS SERIES ROTOSTACCIO

Description

The rotostrainer RTS is a machine that is used for the filtration of sewage effluent coming from the pre-treatment of civil or industrial purification plants or more generally for the screening of process water coming from industrial processing plants, such as fruit and vegetable processing industries, meat and fish processing industries, and slaughterhouses; other sectors of use may include tanneries, paper mills, and wine industries. It consists of a body made of Aisi 304L stainless steel sheet and profiles, inside of which a filter made of Aisi 304L stainless steel rotates with a surface consisting of a special spiral-wound Aisi 304L stainless steel V-profile, with a distance between the coils equivalent to the desired filtration span.

It consists of a body made of Aisi 304L stainless steel sheet and profiles, inside of which a filter made of Aisi 304L stainless steel rotates with a surface consisting of a special spiral-wound Aisi 304L stainless steel V-profile, with a distance between the coils equivalent to the desired filtration span.

Functioning:

The liquids to be filtered flow through a flanged nozzle to the inlet tank and are conveyed, through a special distributor equipped with liquid sealing elements, to the surface of the filter, where the separation of the solids takes place. The solids are retained and rotated by the outer surface of the rotating filter and evacuated by a special brass cleaning blade.

The filtered liquid passes through the inside of the filter drum where it exerts an effective backwashing action on the opposite surface of the filter and is conveyed to the tank bottom where it flows to the discharge nozzle.

Advantages:

The main advantages of this machine are: its low cost of purchase, the absence of manpower to run it, the very low frequency of maintenance, the impossibility of clogging the filtering drum, the very low

energy consumption and finally its large flow rate compared to its rather small size. the very low energy consumption and, finally, its great capacity compared to its rather small dimensions. This last characteristic allows the rotostrainer to

be used for applications in overhead canals or in small spaces. thanks to its very small dimensions in relation to the achievable capacities.

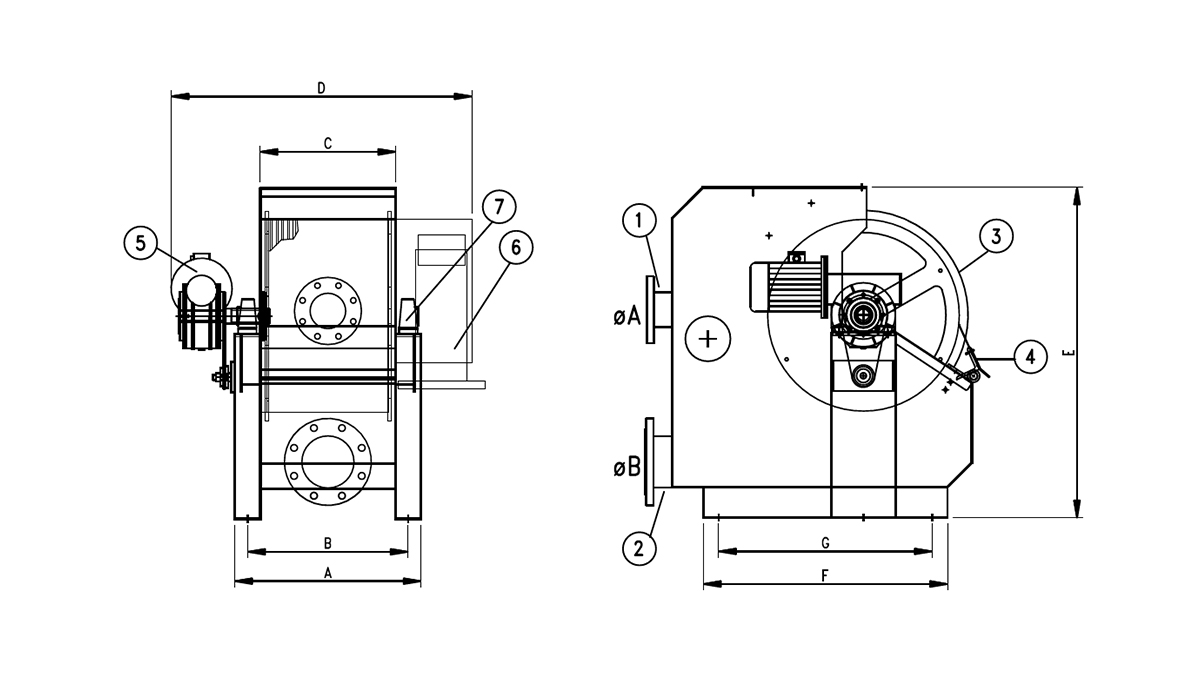

Composition:

- Slurry inlet

- Treated sewage outlet

- Filter cylinder

- Flooding Blade

- Gearmotor

- Too full

- Washing water inlet 1 ”gas m

| Model | A[mm] | B[mm] | C[mm] | D[mm] | E[mm] | F[mm] | G[mm] | ØA[mm] | ØB[mm] |

|---|---|---|---|---|---|---|---|---|---|

| RTS 40/4 | 610 | 530 | 400 | 770 | 700 | 515 | 475 | 80 | 100 |

| RTS 40 | 610 | 525 | 400 | 850 | 1080 | 800 | 700 | 100 | 150 |

| RTS 60 | 810 | 725 | 600 | 1050 | 1080 | 800 | 700 | 200 | 250 |

| RTS 90 | 1110 | 1025 | 900 | 1350 | 1080 | 800 | 700 | 200 | 250 |

| RTS 120 | 1410 | 1325 | 1200 | 1650 | 1080 | 800 | 700 | 250 | 300 |

| RTS 150 | 1710 | 1625 | 1500 | 2130 | 1080 | 800 | 700 | 250 | 300 |

| RTS 180 | 2010 | 1925 | 1800 | 2250 | 1080 | 800 | 700 | 300 | 350 |

| RTS 300 | 3210 | 3150 | 3000 | 3700 | 1700 | 1700 | 785 | 400 | 500 |

Bring in mc/h ***

| Spacing | 0.25 mm | 0.50 mm | 0.75 mm | 1.00 mm | 1.20 mm | 1.50 mm | 2.00 mm | 2.50 mm |

|---|---|---|---|---|---|---|---|---|

| RTS 40/4 | - | 10 | 10 | 15 | - | 15 | 15 | 15 |

| RTS 40 | 30 | 50 | 70 | 84 | 95 | 110 | 118 | 120 |

| RTS 60 | 60 | 105 | 140 | 175 | 195 | 218 | 235 | 240 |

| RTS 90 | 90 | 153 | 212 | 258 | 295 | 333 | 358 | 360 |

| RTS 120 | 118 | 208 | 278 | 345 | 387 | 436 | 468 | 470 |

| RTS 150 | 150 | 260 | 350 | 420 | 480 | 530 | 600 | 660 |

| RTS 180 | 183 | 280 | 425 | 514 | 587 | 664 | 712 | 720 |

| RTS 300 | 420 | 720 | 1000 | 1200 | 1400 | 1600 | 1900 | 2100 |

***The flow rates indicated in the table are indicative and refer to sewage with suspended solids equal to 200 ppm by volume.

Sizes and weights

| Spacing | Cilinder [mm] | Sizes [mm] | Power [Kw] | Weight [Kg] | |

|---|---|---|---|---|---|

| Length | Diameter | ||||

| RTS 40/4 | 400 | 405 | 800x780x700h | 0.37 | 150 |

| RTS 40 | 400 | 628 | 1130x910x1080h | 0.55 | 200 |

| RTS 60 | 600 | 628 | 1130x1235x1080h | 0.55 | 240 |

| RTS 90 | 900 | 628 | 1130x1535x1080h | 0.55 | 270 |

| RTS 120 | 1200 | 628 | 1130x1835x1080h | 0.55 | 300 |

| RTS 150 | 1500 | 628 | 1130x2130x1080h | 0.55 | 330 |

| RTS 180 | 1800 | 628 | 1130x2230x1080h | 0.55 | 360 |

| RTS 300 | 3000 | 900 | 1700x1660x2000h | 1.1 | 820 |