SPS: il sistema SCAE per le soluzioni di polielettrolita

SCAE, in forza della ventennale esperienza nell'ambito della disidratazione di fanghi e affini, offre sistemi integrati per la preparazione in automatico di soluzioni di polielettrolita in polvere ed in emulsione che includono anche le contestuali attività di formulazione e controllo oltre alla manutenzione ordinaria dell’apparato. Un approccio del tutto innovativo volto a sgravare il committente da qualsivoglia incombenza compreso l’approvvigionamento dei “chemicals”.

SPS - Sistemi Integrati per la preparazione di soluzioni elettrolita

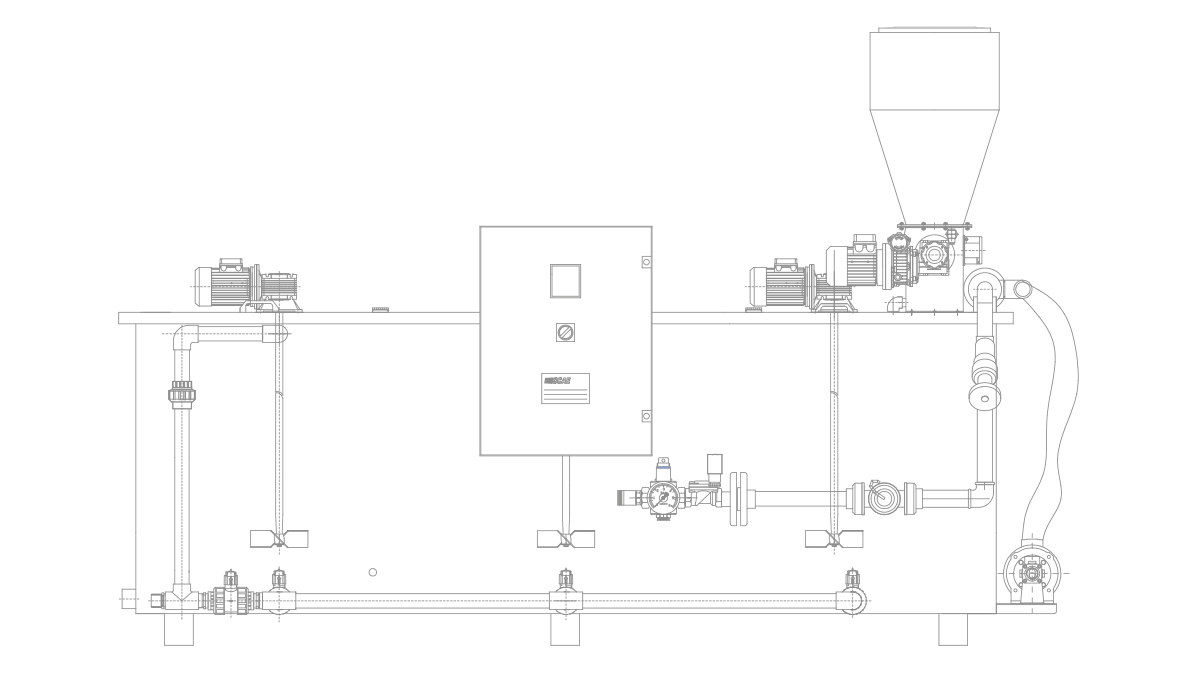

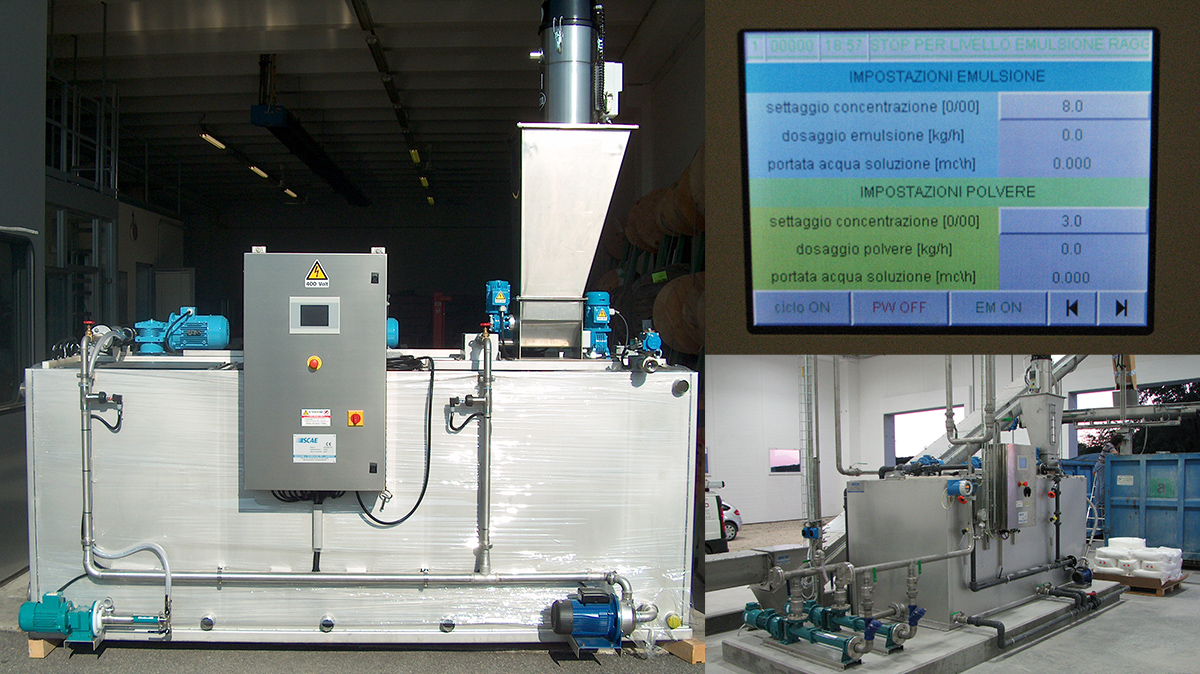

I polipreparatori PPA di SCAE sono sistemi automatici per la preparazione in continuo di soluzioni di polielettrolita a partire dal prodotto in polvere e/o in emulsione. Vengono utilizzati prevalentemente nei processi di disidratazione meccanica dei fanghi realizzati con estrattori centrifughi. La loro funzione primaria è quella di ottenere soluzioni di polielettrolita alla concentrazione desiderata in modo assolutamente automatico senza sprechi di prodotto e con una perfetta dispersione ed omogeneizzazione delle stesse.

L’impianto comprende un sistema di stoccaggio e dosaggio polvere, un eventuale sistema di dosaggio del prodotto in emulsione tramite pompa a pistone, un sistema di diluizione e dispersione , un gruppo di regolazione acqua, una vasca a tre scomparti comunicanti tra loro per tracimazione ed un quadro elettrico per il controllo ed il comando del sistema.

I polipreparatori SCAE si suddividono in due distinte macrocategorie, BASIC e TOP, all’interno delle quali troviamo altri sottogruppi suddivisi in base al polielettrolita trattato: in polvere, in emulsione o in entrambe le modalità.

PPA

POLIPREPARATORE AUTOMATICO PER POLVERE / EMULSIONE

Dati tecnici

|

Materiale trattato |

Polielettrolita in polvere/emulsione |

|

Capacità |

fino a 10.000 lt |

|

Portata |

fino a 10.000 lt/h |

|

Agitatori |

fino a n. 03 |

|

Capacità tramoggia |

300 lt |

Materiali ed Esecuzioni

|

Vasca |

Acciaio inox AISI 304 o Polipropilene |

|

Albero e girante agitatore |

Acciaio inox AISI 304 |

|

Tramoggia |

Acciaio inox AISI 304 |

|

Coclea di dosaggio |

Acciaio inox AISI 304 |

|

Carpenteria Quadro elettrico |

Acciaio verniciato o Acciaio inox AISI 304 |

Accessori compresi

|

• Resistenza anticondensa su tramoggia |

|

• Sensore polvere su tramoggia |

Accessori optionals

|

• Sensore di livello ad ultrasuoni per serbatoio esterno del polielettrolita in emulsione |

|

• Scarichi di fondo valvolati |

|

• Kit taratura, calibrazione ed aspirazione elettropompa monovite con cilindro graduato |

|

• Caricatore pneumatico |

|

• Versione Bi-Fuel per gestione polipreparatore con polvere ed emulsione insieme |

POLIPREPARATORE AUTOMATICO SOLO EMULSIONE MONOVASCA

Dati tecnici

|

Materiale trattato |

Polielettrolita in emulsione |

|

Capacità |

fino a 1.500 lt |

|

Portata |

fino a 16.000 lt/h |

|

Agitatori |

n. 01 |

Materiali ed Esecuzioni

|

Vasca |

Acciaio inox AISI 304 o Polipropilene |

|

Albero e girante agitatore |

Acciaio inox AISI 304 |

|

Carpenteria Quadro elettrico |

Acciaio verniciato o Acciaio inox AISI 304 |

Accessori optionals

|

• Sensore di livello ad ultrasuoni per serbatoio esterno del polielettrolita in emulsione |

|

• Scarichi di fondo valvolati |

|

• Kit taratura, calibrazione ed aspirazione elettropompa monovite con cilindro graduato |

SCAE fornisce una gamma completa di prodotti chimici di base e formulati per ogni applicazione industriale, fra cui quelle inerenti il settore alimentare, il beverage, la lavorazione delle carni, il caseario e così via.

POLVERI E EMULSIONI

Nel corso degli anni SCAE è riuscita a conquistare un solido corollario di Clienti composto da importanti nomi di industrie che si affidano al nostro rapido ed efficiente servizio di fornitura dei chemicals per produrre soluzioni polielettrolita in modo sostenibile con ridotto impatto ambientale.

I prodotti trovano impiego in tutti i processi di purificazione delle acque di scarico civili e industriali, contenenti inquinanti di diversa natura a seconda dei processi di lavorazione e si rivolgono in particolar modo alle aziende che hanno la necessità di depurare le acque per poterle riutilizzare all’interno dei processi in uso ottimizzandone

la produttvità ovvero riducendo drasticamente gli sprechi e i costi di esercizio.

SCAE si focalizza sulle concrete esigenze di processo supportando i propri clienti con formulazioni speciali personalizzate per garantire il miglior trattamento dei fanghi e la depurazione delle acque reflue.

FORMULATI PERSONALIZZATI

A fronte di un’esperienza pluriennale su svariati comparti merceologici, SCAE sviluppa formulazioni polielettrolita personalizzate per soddisfare esigenze particolari del cliente o di una determinata applicazione. Direttamente o in collaborazione con i nostri partner, aiutiamo le aziende a risolvere con efficienza e sicurezza i loro processi di trattamento andando oltre alla semplice funzionalità e senza perdere di vista il delicato tema del rispetto ambientale.

La formulazione di soluzioni poliettrolite dipende dalla specifica applicazione e dalle esigenze del processo, ma generalmente comprende i seguenti passaggi:

- selezione del tipo di poliettrolita

- calcolo della concentrazione

- scioglimento

- regolazione del pH

- controllo della concentrazione

- test e ottimizzazione

- stoccaggio e manipolazione

SCAE è in grado di offrire un servizio di consulenza e di assistenza sia in fase di progettazione che di realizzazione, includendo anche le consuete attività di manutenzione ordinaria e pulizia straordinaria dell’apparato.