Mobile Dewatering Rentals

SCAE meets the customers’ needs providing a single or more pieces of equipment for a fixed period of time (e.g. a week, a month, a year). The maintenance and the initial configuration of the equipment is performed by SCAE, which maintains the property of the machines.

Machine rental on mobile solutions.

MOBILE UNITS

SCAE is delighted to offer to the customers its Know-how and its decades’ experience in the field of wastewater providing its best rental solutions and all the services related, both for short and long periods of time.

The “SCAE RENT” mobile units are made up of first-class machinery giving the system the highest degree of functionality and reliability.

- ZEUS EASY PRESS – production capacity adapted to customer needs

- Sludge pump

- Polymer Automatic Preparation Unit

- Polymer solution pump

- Flow meter for sludge

- Flow meter for polymer

- Screw conveyor system for the management of the dehydrated part

Sludge dehydration is nowadays one of the biggest priorities for those who own or oversee a sludge treatment plant. The dehydration process, necessary to significantly reduce the volume of the wastewater to be managed, is now more essential than ever in order to reduce business costs and optimize sewage treatment.

SCAE, thanks to its mobile plants Plug&Play equipped with the latest technology in the field of sludge separation in terms of performance and low running cost, that is the Zeus Easy Press, can provide fast and efficient support to all those customers who do not have a dehydration plant or those who are passing through a plant downtime.

The sludge is extracted directly from the tank or from the sludge thickener, conditioned with suitable polymer and separated silently and efficiently.

The solid dehydrated part is brought by the conveyors system directly to the bins provided by the client, while the liquid part is sent to the discharge drain.

RELATED SERVICES

The technicians' professionalism of SCAE is provided along all the steps of the renting time in order to assure excellent results in every context of application.

- on-site inspection and evaluation of the client's needs

- analysis of the sludge to be treated in the lab and consequent choice of the most proper polymer

- delivery and collection of the mobile unit

- positioning, connection and subsequent arrangement of the installation on the worksite

- personnel training

- quick answer in case of any intervention by a specialist technician

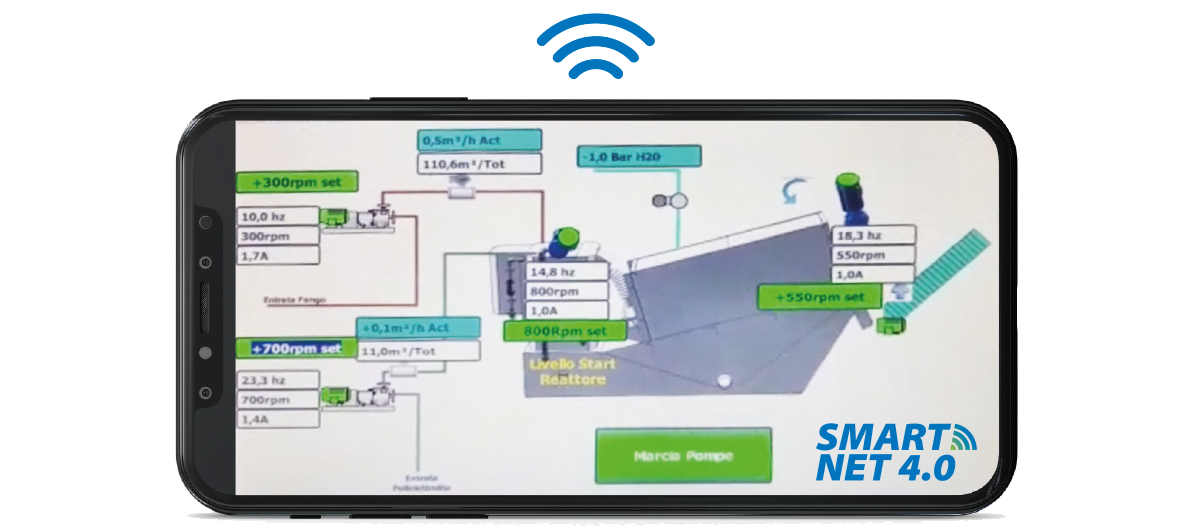

The SCAE RENT mobile units are fully automated and are remotely managed by the SCAE SMART NET 4.0 remote control system.

The SCAE RENT division also provides, on request, the full-time presence of the rent service processing specialist operator.

SCAE can provide sludge dehydration with a mobile unit set up on a skid-compact complete with all the pieces of equipment in order to combine modern technology with a considerable and efficient capacity for product treatment.

Compact 402

MOBILE UNIT SET UP ON SKID-COMPACT FOR SLUDGE DEHYDRATION

This Unit is made up of a Stainless Steel AISI 304 frame with dimensions 2000x1300 mm, with a whole dehydration unit complete of:

- no. 1 SCAE ZEUS 402 Easy Press complete with flocculation tank; all utilities are connected to a VFD;

- no. 1 SYDEX progressing cavity pump for product feeding connected to a VFD;

- no. 1 sludge flow meter;

- no. 1 “Dosatron” system for polymer dosing in the water;

- no. 1 mixer to optimize polymer dissolution in the water;

- no. 1 Polymer in solution flow meter;

- no. 1 pressure transducer for mains water;

- no. 1 electrical panel.

SCAE can provide sludge dehydration with a mobile unit set up on a skid-compact complete with all the pieces of equipment in order to combine modern technology with a considerable and efficient capacity for product treatment.

Skid 604

MOBILE UNIT SET UP ON SKID FOR SLUDGE DEHYDRATION

This Unit is made up with a roll-off with curtain side container with dimensions 6.500 x 2.550 mm, with a whole dehydration unit complete of:

- no. 1 SCAE ZEUS 604 Easy Press complete with flocculation tank; all utilities are connected to a VFD;

- no. 1 SYDEX progressing cavity pump for product feeding connected to a VFD;

- no. 1 SYDEX progressing cavity pump for polymer solution dosing connected to a VFD;

- no. 1 SCAE Polymer Preparation Unit model PPA 500 TOP connected to a VFD with a production capacity of up to 6000 l/h solution;

- no. 1 Polymer in emulsion flow meter;

- no. 1 sludge flow meter;

- no. 1 Polymer in solution flow meter;

- no. 1 tank for the clarified with a pump;

- no. 1 water tank with water pressurization pump;

- no. 1 air compressor;

- no. 1 mixer DN 80;

- no. 1 pressure transducer of mains water;

- no. 1 pressure transducer of mains air;

- no. 1 solids suspended meter in input;

- no. 2 screw conveyors for dehydrated sludge discharge;

- no. 1 electrical control panel for the mobile unit;

- no. 1 electrical distribution panel.

SCAE can provide sludge dehydration with a mobile unit set up complete with all the pieces of equipment in order to combine modern technology with a considerable and efficient capacity for product treatment.

Skid 706

MOBILE UNIT SET UP ON SKID FOR SLUDGE DEHYDRATION

This Unit is made up with a roll-off with curtain side container with dimensions 6.500 x 2.550 mm, with a whole dehydration unit complete of:

- no. 1 SCAE ZEUS 706 Easy Press complete with flocculation tank; all utilities are connected to a VFD;

- no. 1 SYDEX progressing cavity pump for product feeding connected to a VFD;

- no. 1 SYDEX progressing cavity pump for polymer solution dosing connected to a VFD;

- no. 1 SCAE Polymer Preparation Unit model PPA 500 TOP connected to a VFD with a production capacity of up to 6000 l/h solution;

- no. 1 Polymer in emulsion flow meter;

- no. 1 sludge flow meter;

- no. 1 Polymer in solution flow meter;

- no. 1 tank for the clarified with a pump;

- no. 1 water tank with water pressurization pump;

- no. 1 air compressor;

- no. 1 mixer DN 80;

- no. 1 pressure transducer of mains water;

- no. 1 pressure transducer of mains air;

- no. 1 solids suspended meter in input;

- no. 2 screw conveyors for dehydrated sludge discharge;

- no. 1 electrical control panel for the mobile unit;

- no. 1 electrical distribution panel.

SCAE can provide sludge dynamic thickening by using a compact mobile unit complete with all the pieces of equipment in order to combine modern technology with a considerable and efficient capacity for product treatment.

Compact C402ID

COMPACT MOBILE UNIT FOR SLUDGE THICKENING

This Unit is made up of a Stainless Steel AISI 304 frame with dimensions 3.400 x 1.200 mm, with a whole thickening unit complete with:

- no. 1 SCAE ZEUS 402 ID Easy Press complete with flocculation tank; all utilities are connected to a VFD;

- no. 1 SYDEX progressing cavity pump for product feeding connected to a VFD;

- no. 1 SYDEX progressing cavity pump for polymer solution dosing connected to a VFD;

- no. 1 SCAE Polymer Preparation Unit model PPA 500 TOP connected to a VFD with a production capacity of up to 6000 l/h solution;

- no. 1 Polymer in emulsion flow meter;

- no. 1 sludge flow meter;

- no. 1 pressure transducer of mains water;

- no. 1 electrical panel