Mechanical sludge dewatering unit

ZEUS is a monoblock package for thickening and/or dewatering sludge in civil and industrial wastewater treatment plants. At maximum operating speed our Auger Press has low operating and maintenance costs that more than compensate for the lower costs of sludge transport and disposal, generating real savings in economic terms and a tangible advantage for the environment.

With the ZEUS Screw Press, it is possible to achieve sludge thickening up to 10% DS or sludge dewatering beyond 30% DS, depending on the chemical, physical, and biological characteristics of the sludge to be treated in each individual plant.

The ZEUS offers a valid solution for both sludge thickening and dewatering in small and medium-sized sewage treatment plants, both civil and industrial. It can be also successfully applied in various industrial processes that require solid-liquid separation by flocculation. Low operating and maintenance costs and a compact design have been the objectives that SCAE s.r.l. has achieved over the years with feasibility studies, technical design, control tests and the realisation of a line of ready-to-use machines with different execution configurations.

262 ÷ 808

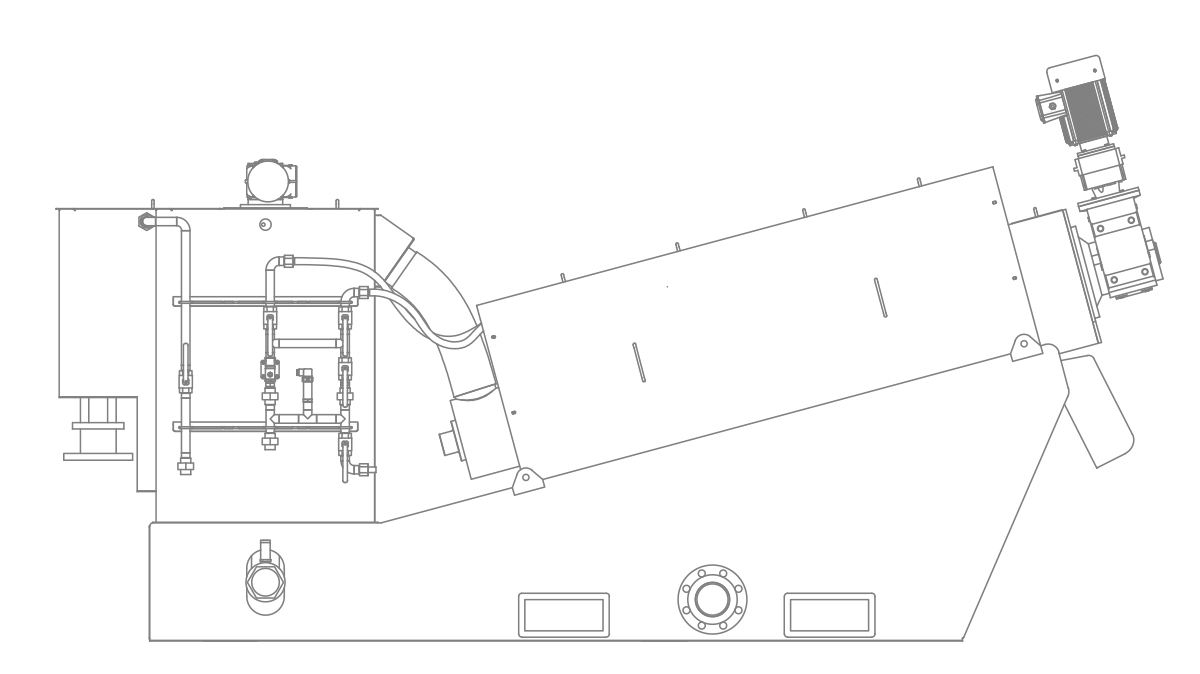

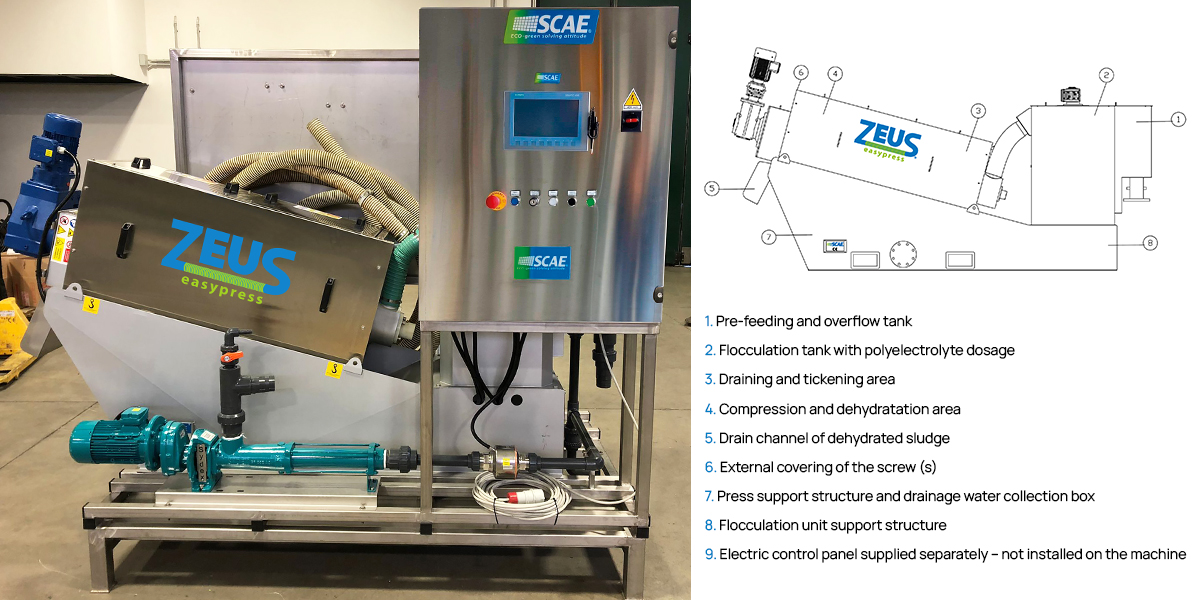

The ZEUS has all the equipment to complete the dehydratation section such as: the single screw electric pumps for feeding the sludge and for the polyelectrolyte dosage, sludge and polyelectrolyte flow meters, the polyelectrolyte preparation station and any augers for transporting the dehydratated sludge.

In this way the Zeus press turns to be a complete monobloc treatment package.

Description:

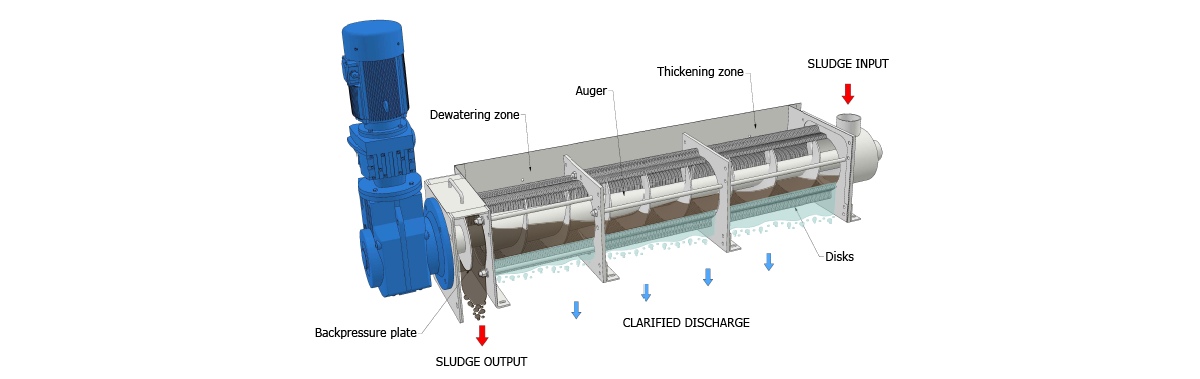

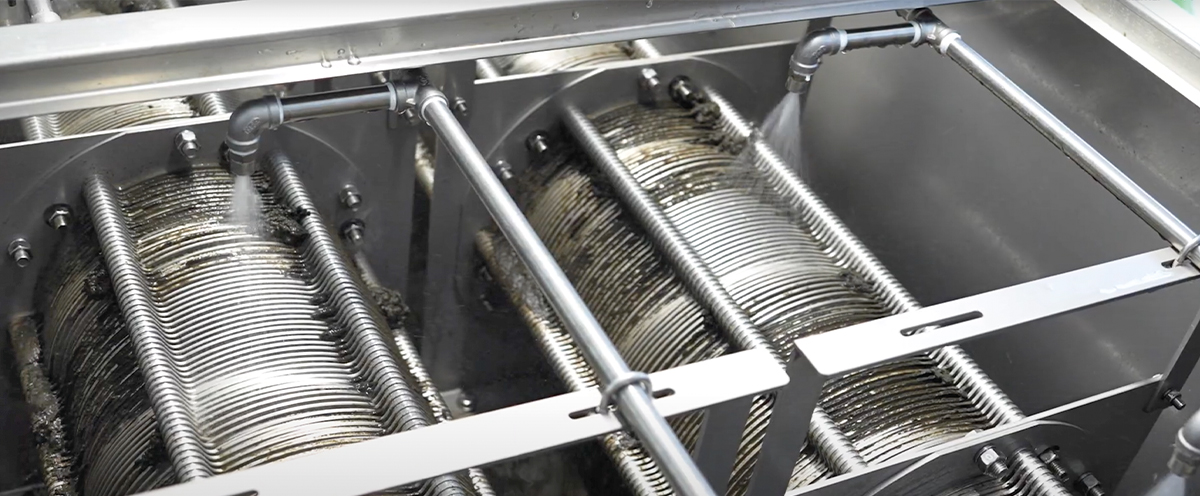

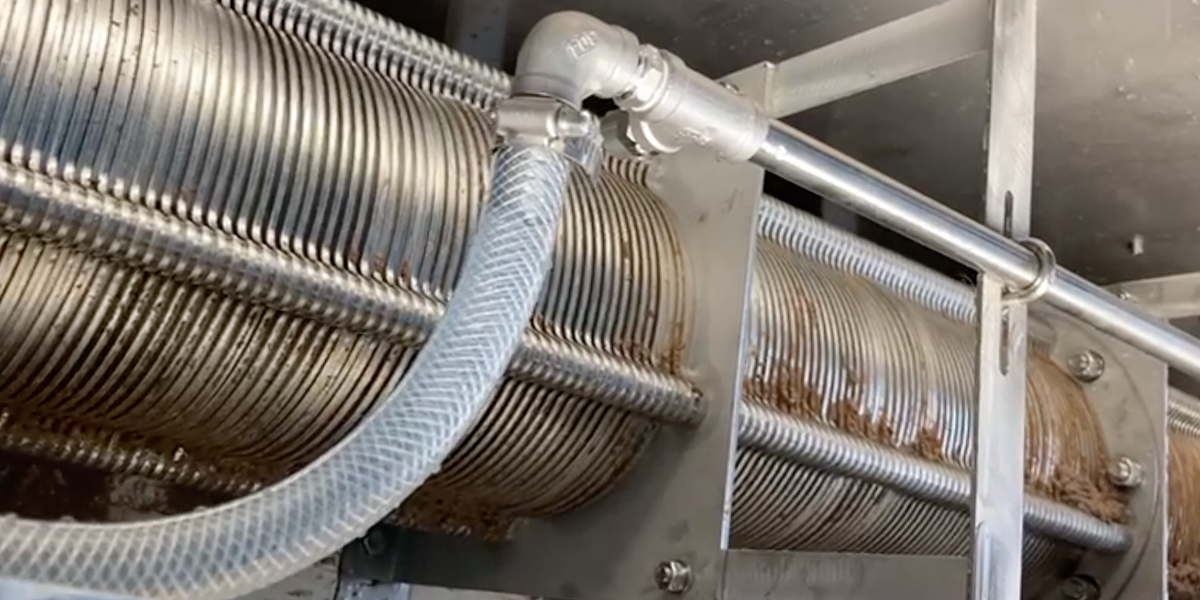

The main part of the ZEUS press consists of one or more screw augers (depending on the different models) with shaft. This axis flows inside a kind of channel made by alternated fixed and moving discs. These discs are entirely made of AISI 304 or 316L stainless steel.

The sludge enters from the sludge inlet area positioned at the beginning of each single pressing screw after being conditioned in the special flocculation tank; then, it is transported by the spiral movement of the auger and finally it is progressively dehydratated and compacted.

The water is separated from the sludge through the space created between the moving discs; this movement also promotes the continuous self-cleaning of the spaces between them, consequently it prevents the obstruction or the blockage of the machine. Thanks to this innovative system, the machine needs a lower washing water quantity than the other types of equipment on the market as regards dehydratation sludge.

ZEUS ⚡️by Scae s.r.l. boasts unprecedented features of maintenance, modularity, and operational continuity:

✓ due to the absence of bearings and thanks to the presence of a single Teflon bushing, the machine does not require continuous lubrication, unlike other sludge dewatering systems;

✓ extraordinary maintenance focuses on the future replacement of the discs, an activity typically carried out after 5–10 years of machine operation;

✓ the press design has been conceived to facilitate this operation, thanks to the possibility of removing the screw from above by opening the casing;

✓ the "multi-screw" configuration allows maintenance activities to be managed without machine downtime. The morphology of the disc screw press enables operation even with one (or more) screws under maintenance, allowing, with proper scheduling, the balancing of maintenance activities with operational needs.

Vantaggi

Pros:

- Self-cleaning, it requires very small quantities of washing water;

- Compact shape and small overall dimension;

- Constant and automatic operation 24/24 hours with minimum operator presence request;

- Reduced and simple maintenance and cleaning;

- It has no rotors which require periodic maintenance;

- Low power requirements and reduced energy consumption compared to other systems ;

- High reliability and long-lasting quality;

Applications:

- urban sewage;

- food and beverage industry;

- dairy industry;

- slaughterhouses and meat processing;

- textile industry and laundries;

- pulp and paper industry;

- chemical and pharmaceutical industry;

- oil and hydrocarbons industry;

- leather and hide processing;

- animal breeding;

- biogas plants from agricultural matrices and industrial waste;

- mining and metallurgical industry.

Main technical features:

| Series | Model | Nominal Diameter screws and N° | Dimension (mm) | Weight (kg) | Flow-rate (lt/h) at 2 bar | Installed power (kW) | |||

|---|---|---|---|---|---|---|---|---|---|

| Lenght | Width | Height | Dry | In process | |||||

| SMALL | |||||||||

| ZEUS 402 | 200×1 | 2465 | 585 | 1535 | 400 | 650 | 50 | 0,55 | |

| 600 | ZEUS 602 | 300×1 | 3330 | 725 | 1890 | 860 | 1250 | 50 | 1,3 |

| ZEUS 604 | 300×2 | 3530 | 1115 | 1875 | 1300 | 1900 | 100 | 2,05 | |

| 700 | |||||||||

| ZEUS 704 | 350×2 | 3920 | 1375 | 2180 | 3100 | 4700 | 140 | 2,95 | |

| ZEUS 706 | 350×3 | 4120 | 1915 | 2180 | 3920 | 5430 | 210 | 4,4 | |

| ZEUS 708 | 350×4 | 4685 | 2755 | 2180 | 5700 | 7710 | 280 | 5,5 | |

| 800 | |||||||||

| ZEUS 804 | 400×2 | 3920 | 1375 | 2180 | 3300 | 4900 | 160 | 3,75 | |

| ZEUS 806 | 400×3 | 4120 | 1915 | 2180 | 4350 | 6750 | 240 | 5,6 | |

| ZEUS 808 | 400×4 | 4685 | 2755 | 2180 | 6100 | 8960 | 320 | 7,5 | |

Powers and capacities:

| Series | Model | Nominal Diameter screws and N° | Dry matter capacity | |||

|---|---|---|---|---|---|---|

| Concentration range | 20.000 mg/L 2% | 30.000 mg/L 3% | 40.000 mg/L 4% | |||

| SMALL | ||||||

| ZEUS 402 | 200×1 | 8≈20 kg/h | ≈ 0.75 mc/h | ≈ 0.6 mc/h | ≈ 0.5 mc/h | |

| 600 | ZEUS 602 | 300×1 | 20≈60 kg/h | ≈ 2.5 mc/h | ≈ 2 mc/h | ≈ 1.5 mc/h |

| ZEUS 604 | 300×2 | 40≈120 kg/h | ≈ 5 mc/h | ≈ 4 mc/h | ≈ 3 mc/h | |

| 700 | ||||||

| ZEUS 704 | 350×2 | 80≈240 kg/h | ≈ 10 mc/h | ≈ 8 mc/h | ≈ 6 mc/h | |

| ZEUS 706 | 350×3 | 120≈360 kg/h | ≈ 15 mc/h | ≈ 12 mc/h | ≈ 9 mc/h | |

| ZEUS 708 | 350×4 | 160≈480 kg/h | ≈ 20 mc/h | ≈ 16 mc/h | ≈ 13 mc/h | |

| 800 | ||||||

| ZEUS 804 | 400×2 | 135≈320 kg/h | ≈ 13 mc/h | ≈ 10 mc/h | ≈ 8 mc/h | |

| ZEUS 806 | 400×3 | 200≈480 kg/h | ≈ 19.5 mc/h | ≈ 15 mc/h | ≈ 12 mc/h | |

| ZEUS 808 | 400×4 | 266≈640 kg/h | ≈ 26 mc/h | ≈ 20 mc/h | ≈ 16 mc/h | |